Projects

Box Cutter

Successfully managed the removal of existing equipment and the installation of a new box cutter along with downstream handling systems at a major packaging supplier’s production facility. The project scope included full project management of civil, mechanical, and electrical works, as well as the commissioning of all machinery.

Vertical Grinder

Project managed the installation of a new vertical cement grinder for a major microfine grouting contractor. The equipment was supplied out of china and the project included all mechanical, electrical and control systems,installation and commissioning.

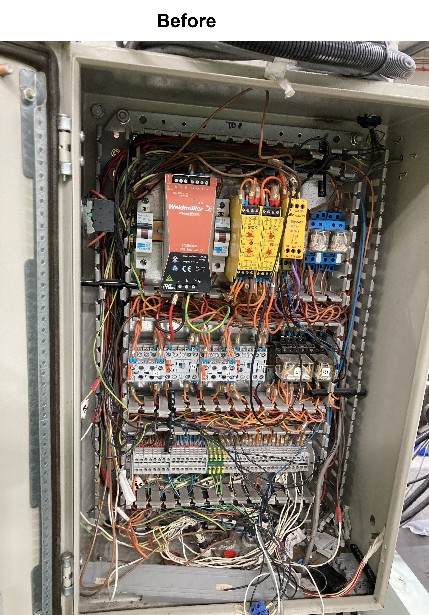

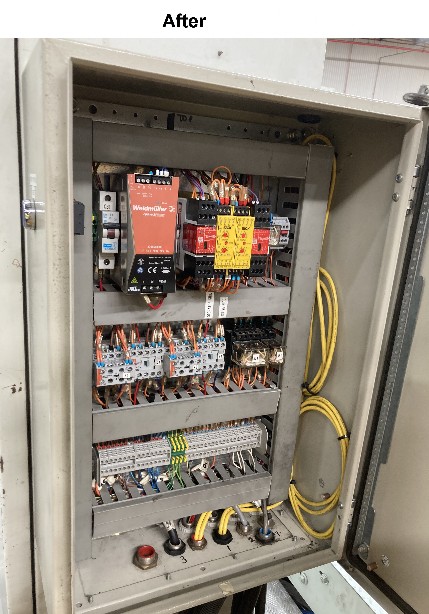

Panel Refurbishment

Recent project involved the installation of an older gluing machine at a prominent plant. The installation included the mechanical and electrical installation and upgrades to electrical panels to ensure they met current standards.

Improvement Projects

Assisting at a pharmaceutical company with improvement projects that included monitoring the filling and packaging equipment, recording areas of improvement and designing and implementing solutions.

Product Camera System

Installed and set up an industrial camera used to detect fill levels and defects in the products on a materials handling system at a pharmaceutical company.

Vial Filling Machine

Project managed the electrical and control systems installation of a new Vial Filling Machine at a pharmaceutical company. The tasks included obtaining quotes, ordering equipment, managing the installation and testing of the facility and equipment.

Robot Replacement

Project managed the replacement of two IRB 140 Robots on a manufacturing material handling machine. Tasks included organising the requirements, quotes, issuing orders, budget management, managing the installation and testing of the system.

Laundry PLC systems

Assisting a laundry service with their diagnostics and repairs on their B&R PLC system that controls their laundry sorting system.

Repairs to Rail Truck Jack Systems

Writewell Systems have been involved in the diagnostics and repairs of 25 tonne rail jack systems. Some of the tasks have taken place in remote areas where spare parts were not available. To overcome a faulty part the PLC was rewired and reprogrammed utilizing spare inputs and outputs and the system was returned to service.

Diagnostics and Repairs

Assisting manufacturing companies with the diagnostics and repairs on their filling and packaging equipment. Some tasks have included locating and supplying replacement hardware for the control systems.

Train Wash Systems

Provided and programmed a Modicon PLC control system for train wash systems at a remote rail yard.

Clean Room Door Control

Assisted an electrical company with the supply and programming of a control system for the Clean Room Door Interlocking at an Oncology department in a major hospital.

Heavy Vehicle Wash System

Provided an Allen Bradley PLC control system and programming for automatically controlled heavy vehicle and light vehicle wash systems at a mine site. This system involved developing control communications between the Allen Bradley Ethernet communications and robotic water cannons communicating using CAN J1939 communications.

Multi Robot System

Set up and program a multi-robot system that included an IRB140 and an IRB340 for pick and place operations at a company that provides farming equipment.